| Stainless steel corrugated packing | | | | | [Corrugated packing]

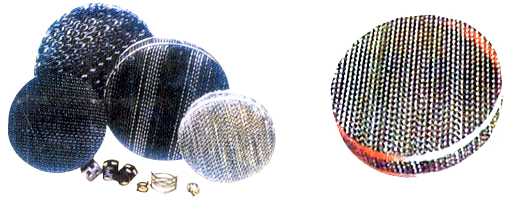

Our guide in Shanghai Chemical Industry Research Institute, specializing in the production of new and efficient corrugated structured packing and random packing, can be stainless steel, copper, aluminum, titanium, molybdenum five titanium, and other materials produced. In fragrances, pesticides, fine chemical, petrochemical and other fields are widely used. Structured packing is divided into a mesh, screen, plate, rolled plates and the like. Random packings are: metal Pall ring packing, metal ladder ring packing, metal ring saddle that British Teluo Si filler metal. Our guide in Shanghai Chemical Industry Research Institute, specializing in the production of new and efficient corrugated structured packing and random packing, can be stainless steel, copper, aluminum, titanium, molybdenum five titanium, and other materials produced. In fragrances, pesticides, fine chemical, petrochemical and other fields are widely used. Structured packing is divided into a mesh, screen, plate, rolled plates and the like. Random packings are: metal Pall ring packing, metal ladder ring packing, metal ring saddle that British Teluo Si filler metal. |  | | sw-type mesh packing geometry parameters | | Packing Model | Material | Peak heighth mm | The specific surface aream2/m2 | Hydraulic diameterah/mm | Tilt angle | Porosity% | fFactorm/s kg/m2 | Theoretical platesno/m | Pressure dropmmhg/m | | SW-1型 | Stainless steel | 4.5 | 643 | 5.7 | 45 | 91.6 | 1.4-2.2 | 5-8 | 2-3.5 | | SW-1型 | 6.5 | 450 | 9 | 30 | 95.5 | 1.5 | 4-5 | 1.6-1.8 |

| | Corrugated packing geometry parametersSC=CY SB=BX | | Packing Model | Material | Peak heighth mm | The specific surface aream2/m2 | Hydraulic diameterah/mm | Tilt angle | Porosity% | fFactorm/s kg/m2 | Theoretical platesno/m | Pressure dropmmhg/m | | CY | Stainless steel | 4.3 | 700 | 5 | 45 | 87-90 | 1.3-2.4 | 6-9 | 5 | | BX | 6.3 | 500 | 7.3 | 30 | 95 | 2-2.4 | 4-5 | 1.5 |

| | Corrugated plate packing geometry parameters | | Packing Model | Material | Peak heighth mm | The specific surface aream2/m2 | Hydraulic diameterah/mm | Tilt angle | Porosity% | fFactorm/s kg/m2 | Theoretical platesno/m | Pressure dropmmhg/m | | SM125 | Stainless steel | 24 | 125 | 35 | 45 | 98.5 | 3 | 1-1.2 | 1.5 | | SM225 | 12 | 250 | 15.8 | 45 | 97 | 2.6 | 2-3 | 1.5-2 | | SM325 | 8 | 350 | 12 | 45 | 95 | 2 | 3.5-4 | 1.5 | | SM425 | 6.5 | 450 | 9 | 45 | 93 | 1.5 | 3-1 | 1.8 |

| | Rolling corrugated plate packing geometry parameters | | Packing Model | Material | Peak heighth mm | Peak heighth mm | Porosity% | The specific surface aream2/m2 | Hydraulic diameterah/mm | fFactorm/s kg/m2 | | 700Y | Stainless steel | 5-7 | 4.3 | 85 | 700 | 7 | 1.6 | | 500X | 3-4 | 6.3 | 90 | 500 | 2 | 2.1 | | 250Y | 2.5-3 | | 97 | 250 | 2.25 | 2.6 |

|

|

|

|

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.