| Z series of highly efficient rotary film evaporator | | | | | I. Overview

Produced by the company's Z series rotary blade manufacturing thin-film evaporator, is a mandatory film by rotating blades, can be new and efficient evaporator falling film evaporator under vacuum conditions. It is the heat transfer coefficient, high evaporation strength, flow time is short, operating flexibility, especially suitable for sensitive materials, high-viscosity materials and concentrated by evaporation and crystallization containing particulate materials, degassing desolventizing, purified by distillation. Therefore, in the chemical, petrochemical, pharmaceutical, pesticide, cosmetic, food, chemical and other industries widely used.

My company manufacturing such devices has more than ten years, has accumulated rich experience in the manufacture and use. Over the years, according to market demand, closely combined with the user's actual production process to meet the user's requirements as a precondition, a reasonable choice of suitable equipment structure, to ensure reliable manufacturing superior quality, tooling equipment, testing methods and product design and other aspects of continuous improvement and maturing, has made remarkable achievements, technical level and product quality in the domestic leading level. My company manufacturing such devices has more than ten years, has accumulated rich experience in the manufacture and use. Over the years, according to market demand, closely combined with the user's actual production process to meet the user's requirements as a precondition, a reasonable choice of suitable equipment structure, to ensure reliable manufacturing superior quality, tooling equipment, testing methods and product design and other aspects of continuous improvement and maturing, has made remarkable achievements, technical level and product quality in the domestic leading level.

Second, the structural characteristics

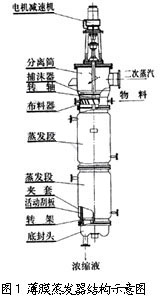

Z series thin film evaporator, the main structure shown in Figure 1, the structures are as follows:

1 motor, reducer

It is the drive means for rotating the rotor. The rotational speed of the rotor blade from the viscosity depends on the form of the inner diameter of the barrel, and evaporated material; select the appropriate line speed blade is guaranteed stable and reliable operation of the evaporator and the evaporation effect of one satisfactory important parameters.

2 separate tube

Separating the material from the barrel provided at the lower end of the tangential inlet of the evaporator, and the separator installed in the barrel through the hopper is continuously evaporated uniformly distributed in the inner wall of the barrel, the barrel was evaporated from the evaporation of the secondary steam rising to the separation cartridges, including the installation of a gas-liquid separator, the secondary steam entrained droplets or bubbles may be separated from the upper end of the secondary lead vapor from the evaporator outlet.

Flashlight rational design based on the separation of the resistance in the evaporator calculations, is one of the key factors to avoid material "short circuit" of. (So-called "short-circuit" means the material first entered the evaporator, the evaporation process has not been completed, the secondary steam from exiting the evaporator outlet.)

3. Distributor

Fabric is mounted on the rotor. Rational design, so entering the evaporator material from the tangential direction by rotating the distributor, the film was continuously poured evenly distributed in the evaporation surface.

4-liquid separator

Rotary vane-type gas-liquid separator is mounted on the top of the separator tube, it may rise secondary steam entrained droplets or foam trap, and allowed to fall to the evaporation surface.

5. Evaporation Flashlight

Also known as the heating barrel. It is forced to rotate the blade and the material forming the jacket of the heat exchange medium is heated evaporation surface. Evaporation barrel diameter and length is determined by the evaporation area and the appropriate aspect ratio.

Heating the inner wall of the barrel by special machining and polishing, and with the ends of flange surfaces on primary processing and to ensure that the center of the device as a whole. After polishing (mirror polished if necessary) of the barrel wall smooth clean bright, easy to stick material and scale, effectively ensuring the equipment's high heat transfer coefficient。

5.1 If the heating medium is steam heated jacketed barrel general form.

5.2 If the heating medium is oil or high-pressure steam, heating barrel half-pipe commonly used form.

6 rotor

Installed in the evaporator barrel rotor shaft and the transfer from the shelf components. The rotor consists of motor, reducer drive, and drive the blade in a circular motion. Turn rack made of stainless steel plastic processing, its strength, geometry, stability and so are effectively guaranteed

7. Scraper

Due to the movement of the blade, the material continuously into a thin film evaporator surface scraping to achieve the effect of the thin film evaporator.

Depending on the viscosity and other characteristics of the material, there are the following four scraper forms are available:

(1) slide blade (see Figure 2)

Slide the blade is a basic, the most common form of scraper. The rotor blade is mounted in the four blade guide groove, the centrifugal force due to rotation of the rotor and radially inner wall surface of the cylinder is thrown to the evaporator, with a circular motion simultaneously with the rotor. This scraping blade, so that the material on the evaporator wall membranous turbulent state, greatly improving the heat transfer coefficient, and this continuous scraping action effectively prevent overheating of the material, the dry wall and fouling phenomenon. |

|

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.