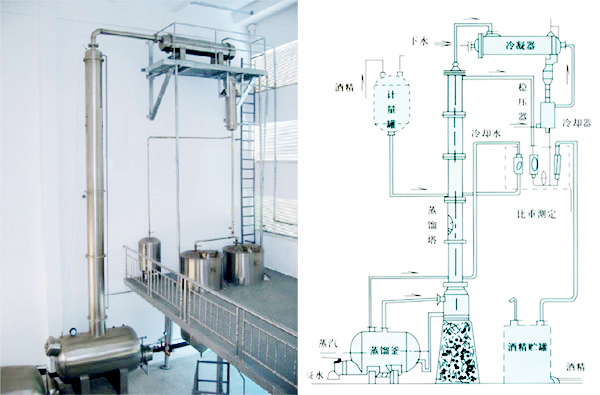

| Alcohol recovery tower | | | | | | This device is intended dilute alcohol recovery pharmaceutical, food, light industry, chemical industry, but also applies to other solvents such as methanol distillation of coal. The device according to the user's needs, according to dilute the alcohol can be distilled about 30 ゜ C to 90 ° C-95 ゜ C alcohol, refined tartaric acid and then high-precision requirements, you can increase the reflux ratio, but production will be reduced accordingly. |  | | The installed high-efficiency stainless steel filler metal. Using stainless steel distillation column, thereby preventing iron block tower packing phenomenon, Director of the period of use the device. Any contact with the device, such as alcohol device part condenser, surge tank, stainless steel cooling coils etc., to ensure that the finished product will not be contaminated alcohol. Stills work with removable U-shaped heat pipe, in the maintenance of the U-shaped heat pipe can be pulled outside the kettle, heating pipe wall and facilitate the distillation kettle wall cleaning. This device can be intermittent production, can also be semi-continuous and continuous production. | Name / Size | JH200 | JH300 | JH400 | JH500 | JH600 | JH800 | Tower volume(L) | 640 | 1220 | 1450 | 2300 | 2500 | 3200 | Tower height(mm) | 6000 | 7000 | 7000 | 7500 | 8000 | 10000 | High tank volume(L) | 300 | 400 | 650 | 800 | 1000 | 1500 | Condensing area(m2) | 5 | 9 | 11 | 22 | 25 | 40 | Cooling area(m2) | 1 | 1.5 | 2.2 | 6 | 8 | 15 | Heat transfer area(m2) | 4 | 6 | 12 | 18 | 25 | 32 | Additional capacity(kg/h) | 45-50 | 90-100 | 150-160 | 280-300 | 420-440 | 600-620 | Recycling concentration(%) | 90゜C-95゜C | Fill in the form | Stainless steel corrugated packing | Weight(Kg) | 1100 | 1900 | 2300 | 3800 | 4500 | 7800 | | 2300×700×8000 | 2600×800×9000 | 2800×1000×9000 | 3000×1200×9000 | 3500×1400×10000 | 4200×1800×14000 |

|

| | |

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.