| Canister vacuum evaporated | | | | | Main purpose:

Mainly used in pharmaceutical, food, chemical and other industrial sectors concentrate on the liquid material. And can also recovering alcoholic and simple reflux extraction.

Structure:

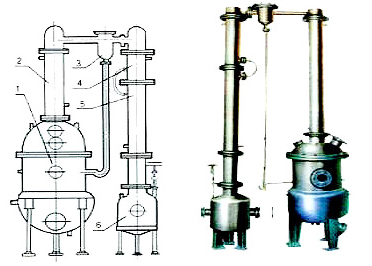

The concentration tank equipment including a first condenser, a vapor-liquid separator, a second condenser, a cooler, a liquid barrel six components, there are all made of stainless steel. Concentrated cans jacket structure, the column tube condenser, cooler snake tube. | A schematic diagram of the major components

A concentrate tank 2, a first condenser 3, the gas-liquid separator 4, the second condenser 5, a cooler 6, by the tank |  | | The main technical parameters | | 50 | 100 | 200 | 300 | 500 | 700 | | Steam pressure Mpa | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | ≤0.15 | | Vacuum degree mmHg | ≤700 | ≤700 | ≤640 | ≤640 | ≤600 | ≤600 | | Heating area M2 | 0.4 | 0.59 | 0.8 | 1.1 | 1.45 | 1.8 | | Condensing area M2 | 1.2 | 1.7 | 2.45 | 3.0 | 3.2 | 3.6 | | Cooling area M2 | 0.25 | 0.35 | 0.4 | 0.6 | 0.7 | 0.85 | | Heated tank volume L | 15 | 45 | 60 | 76 | 100 | 125 | | Net weightkg | ~350 | ~450 | ~550 | ~650 | ~800 | ~1000 | | Dimensions L × W × Hmm | 1200×600

×2200 | 1350×750

×2200 | 1700×800

×2700 | 1700×1000

×3400 | 2100×1200

×3400 | 2400×1300

×3400 |

|

|

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.