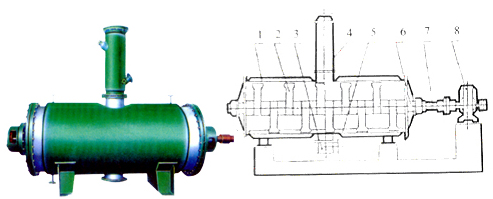

| vacuum rake dryer | | | | | | Has asimplestructure, convenient operation, long life cycle,stable and reliable performance,smallsteam consumption,strong for performance, product quality, especially for not hightemperature, dry flammable, easily oxidized underthermostat paste materials, aircraft by users provedto be a good long-term use of drying equipment. Principle: Founder middle of adding dry material fromthe housing, inthe positive and negativestirring constantly rotating raketeeth,the material axially back and forth, in contact withthe housing wallsurface continuously updated by indirectsteam heating,the raketeethstir crushed crush bar, makethe material more favorablesurface water discharge, water vaporized by dry precipitators, wetscrubbers, condensers, vacuum pump atthe outlet fromthe vent.structure:the main components vacuum rake dryer. |  | 1, case 2, 3 raketeeth, a feeding device 4,the feeding device 5, crushedstick

6,thesealing device 7,thestirringshaft 8,the drive means | | Applicable materials | High muddy paste 100 mesh material of various pigments, dump-like material and centrifuge filter and filter ash detergent,

stone basestarch, dyes and pigments,such as clay, clay and cement gray | | Under appropriate conditions apply | | 100 meshsynthetic materialsolution,the vacuum crystallization, emulsions potato chip, minerals andsuspensions | | Models andtechnical characteristics | | the main parameters Model | Nominal volume | Heattransfer area | A charge | Absolute Operating Pressure | Operatingtemperature | spindlespeed | Material | Weight | Motor Power | Dimensions L × W × H | | Cylinder body | Jacket | | XPG0.5 | 0.5 | 1.86 | 0.2 | 0.021 | 0.686 | 435 | 15-20 | | | Note: 3 | | | Fu: 5.5 | | XPG1 | 1 | 6 | 0.75 | 0.021 | 0.686 | 435 | 9 | A3 | 3400 | 5.5 | 3700 × 945 × 3270 | | 1Cr18Ni9Ti | 3300 | | XPG2 | 2 | 8 | 1.2 | 0.021 | 0.588 | 425 | 9 | A3 | 4900 | 11 | 4570 × 1130 × 3455 | | 1Cr18Ni9Ti | 4800 | | XPG3 | 3 | 11.5 | 11.5 | 1.021 | 0.588 | 425 | 9 | A3 | 6400 | 15 | 6076 × 1130 × 2980 | | 1Cr18Ni9Ti | 6300 |

|

| | |

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.