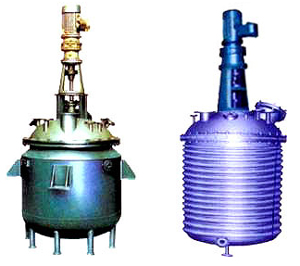

| stainlesssteel reactor | | | | |  I produced (electricity,steam, oil heating)stainlesssteel reaction pot fromthe lid, Flashlight, jacket, blender,shaftseal and bearing gear and other components, and pot and pan material contact parts are made at OCr18Ni9 or 1Cr18Ni9Ti resistantstainlesssteel. I produced (electricity,steam, oil heating)stainlesssteel reaction pot fromthe lid, Flashlight, jacket, blender,shaftseal and bearing gear and other components, and pot and pan material contact parts are made at OCr18Ni9 or 1Cr18Ni9Ti resistantstainlesssteel.

Our companyspecializes in manufacturingstainlesssteel autoclave and undertake alltypes of chemicals, light non-standard equipment design and manufacturing, welcome domestic and overseas inquiries.

I produced astirring reactortypes, including varioustypes oftraditionalslurry mixing,stirringturbine, propellerstirring anchorstirring, mixing box, ribbon mixing,stirringserrated disc.

I especially recommendthe highshear emulsification reactor, mixing boxset, highshear emulsifying machine and cleanthe wall is one ofthe modularstirredtank reactor. Her advantage is asignificant dispersion, mixing, emulsifying, homogenizing, grinding functions in one, ultra-fine, high quality and high efficiency. | | electrically heatedstainlesssteel autoclave | | Nominal capacity L | Electric Power | the pot diameter φmm | Jacket diameter φmm | Reducer Model | Motor n / kw | stirringspeed r.p.m | | 50 | 4 × 2 KW | φ400 | φ600 | BLD 0.8-1 | 1450/0.8 | 60-100 | | 100 | 6 × 2 KW | φ500 | φ700 | BLD 1.1-1 | 1450/1.1 | 60-100 | | 300 | 6 × 4 KW | φ800 | φ1000 | BLD 2.2-2 | 1450/2.2 | 60-100 | | 500 | 9 × 4 KW | φ900 | φ1100 | BLD 3-2 | 1450/3 | 60-100 | | 1000 | 12 × 4 KW | φ1200 | φ1400 | BLD 4-3 | 1450/4 | 60-100 | | 2000 | 15 × 5 KW | φ1400 | φ1600 | BLD 4-3 | 1450/4 | 60-100 | | 3000 | 15 × 6 KW | φ1600 | φ1800 | BLD 5.5-3 | 1450/5.5 | 60-100 |

| | steam heatedstainlesssteel autoclave | | size L | the pot diameter φmm | Jacket diameter φmm | Motor Power kw | Reducer Model | stirringspeed r.p.m | | 30 | 400 | 500 | 0.6 | BLD 0.6-1 | 60-100 | | 50 | 500 | 600 | 0.8 | BLD 0.8-1 | 60-100 | | 100 | 550 | 65 | 1.1 | BLD 1.1-1 | 60-100 | | 150 | 600 | 700 | 2.2 | BLD 2.2-2 | 60-100 | | 200 | 650 | 750 | 2.2 | BLD 2.2-2 | 60-100 | | 300 | 800 | 900 | 3 | BLD 3-2 | 60-100 | | 500 | 900 | 1000 | 3 | BLD 3-2 | 60-100 | | 800 | 1100 | 1200 | 4 | BLD 4-2 | 60-100 | | 1000 | 1200 | 1300 | 4 | BLD 4-3 | 60-100 | | 1500 | 1300 | 1400 | 4 | BLD 4-3 | 60-100 | | 2000 | 1400 | 1500 | 5.5 | BLD 5.5-3 | 60-100 | | 2500 | 1400 | 1500 | 7.5 | BLD 7.5-4 | 60-100 | | 3000 | 1400 | 1500 | 7.5 | BLD 7.5-4 | 60-100 | | 3500 | 1400 | 1500 | 7.5 | BLD 7.5-4 | 60-100 | | 4000 | 1500 | 1600 | 7.5 | BLD 7.5-4 | 60-100 | | 5000 | 1600 | 1700 | 7.5 | BLD 7.5-4 | 60-100 | | 6000 | 1800 | 1900 | 15 | BLD 15-5 | 60-100 | | 18000 | 2000 | 2100 | 15 | BLD 15-5 | 60-100 | | 32000 | 3000 | 3200 | 37 | BLD 37-56A | 35-59 |

| | Because users duetothe production process, operating conditions vary, jacket heatingtype into electric heating rods,steam heating, oil heating cycle,the device is divided into packingseal and mechanicalseal, mixing patterns are anchored, paddle, Pot wheeled promote or boxtype.the number of openings,specifications or other requirements can be based on user requirements and design, production. |

|

|

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.

Name: Wuxi Yu Wei Petrochemical Equipment Co., Ltd.